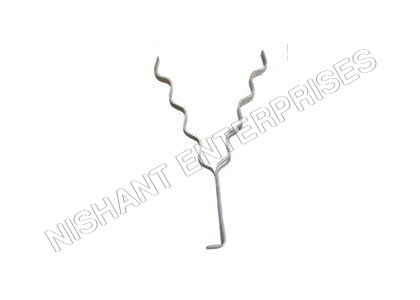

Y Shape Refractory Anchors

Price 400 INR/ Kilograms

Y Shape Refractory Anchors Specification

- Surface Treatment

- Pickled, Polished, Zinc Plated, Sand Blasted

- Finishing

- Bright, Smooth

- Weight

- As per dimension and material selection

- Capacity

- High Temperature and Load Bearing

- Material

- Stainless Steel, Mild Steel, Nickel Alloy, Inconel, Hastelloy, Monel

- Type

- Y Shape

- Length

- 25 mm to 300 mm (Customizable as per requirement)

- Product Type

- Y Shape Refractory Anchors

- Diameter

- 3 mm to 16 mm

- Surface

- Plain, Corrugated, Ribbed

- Grade

- SS 304, SS 310, SS 316, MS, etc.

- Packing

- Bags, Cartons, Wooden Boxes

- Application

- Petrochemical, Steel Plant, Cement Kiln, Power Plant, Boilers, Incinerators, etc.

- Customization

- Available as per customer drawing or sample

- Installation Method

- Welding, Stud Welding, Manual Fixing

- Shape

- Y Type

- Corrosion Resistance

- Excellent for stainless steel grades

- Temperature Resistance

- Up to 1600°C (Depends on grade)

- Design Standards

- ASTM / DIN / Custom

Y Shape Refractory Anchors Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 500 Kilograms Per Day

- Delivery Time

- 2 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- in wooden boxes and carton boxes.

- Main Domestic Market

- All India

About Y Shape Refractory Anchors

By keeping track with market development, we are offering a supreme quality range of Y Shape Refractory Anchors that is used in various industrial sectors, including cement, steel and petrochemical. These are manufactured at our state-of-the-art manufacturing unit using world class raw materials and cutting edge technology in compliance with predefined industry standards. The offered Y Shape Refractory Anchors are known for easy installation, robust construction, corrosion resistant nature and longer functional life. These products are stringently tested on various quality parameters to meet the defined industry standards.

Versatile Applications in Extreme Environments

Y Shape Refractory Anchors are designed for robust performance in high-temperature and high-load settings. Suitable for industries such as petrochemical, steel manufacturing, cement kilns, and power plants, these anchors offer secure, reliable refractory lining attachment. Their corrosion resistance and flexibility in design make them an excellent choice for challenging operational demands.

Custom Engineered for Your Project

Our Y Shape anchors come in various sizes, diameters, and materials, including stainless steel grades (SS 304, SS 310, SS 316), mild steel, and special nickel alloys. We provide customization based on customer drawings or samples, ensuring optimal compatibility with your specific refractory needs. Surface finishes such as pickled, polished, and zinc plated are available to suit diverse installation environments.

FAQs of Y Shape Refractory Anchors:

Q: How are Y Shape Refractory Anchors installed?

A: These anchors can be installed using welding, stud welding, or manual fixing methods, depending on the lining design and project requirements. The installation process should adhere to standard safety procedures, and the selected method ensures secure anchorage within refractory linings.Q: What are the main benefits of using Y Type Refractory Anchors?

A: Y Shape anchors provide excellent load-bearing capacity and exceptional temperature resistance, supporting refractory linings up to 1600C (depending on material grade). Their design offers stability, and when manufactured from stainless steels or nickel alloys, they deliver outstanding corrosion resistance for long-lasting service.Q: When should custom Y Shape Refractory Anchors be considered?

A: Custom anchors should be chosen when standard dimensions do not match the projects specifications or when unique refractory structures require specialized anchor designs. Customization is available based on engineering drawings or physical samples provided by the customer.Q: Where are Y Type Refractory Anchors typically used?

A: Y Shape anchors are extensively used in petrochemical plants, steel factories, cement kilns, power plants, boilers, and incinerators. Their resilience to high temperatures and harsh environments makes them ideal for heavy industrial applications requiring durable refractory attachment.Q: What is the manufacturing process for Y Shape Refractory Anchors?

A: The anchors are fabricated from selected materials such as stainless steel, mild steel, or nickel alloys, and formed into Y shapes through precise forming and welding techniques. After shaping, surface treatments like pickling, polishing, sand blasting, or zinc plating may be applied to enhance performance and durability.Q: How does material selection impact the performance of refractory anchors?

A: Selecting the appropriate material (e.g., SS 304, SS 310, Inconel, Hastelloy) ensures the anchor meets the desired temperature resistance, mechanical strength, and corrosion protection, thus extending the service life and reliability of refractory linings in corrosive or high-temperature environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Anchor Products Category

Stainless Steel Refractory Anchors

Price 400 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Material : Other, Stainless Steel

Product Type : Stainless Steel Refractory Anchors

Diameter : 3 mm to 12 mm

Grade : SS304, SS316, SS310, Inconel, and other alloys

Industrial refractory anchor

Price 400 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Material : Other, Stainless Steel / Mild Steel

Product Type : Industrial refractory anchor

Diameter : 3 mm to 16 mm

Grade : SS 304, SS 310, SS 316, MS

SS Refractory Anchors

Price 400 INR / Piece

Minimum Order Quantity : 50 Pieces

Material : Other, Stainless Steel (SS)

Product Type : SS Refractory Anchors

Diameter : 3 mm to 12 mm

Grade : SS 304, SS 310, SS 316, SS 321 and other grades

Furnace Anchor

Price 400 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Material : Other, Stainless Steel

Product Type : Furnace Anchor

Diameter : As per specification

Grade : 304 / 316 / 310

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS