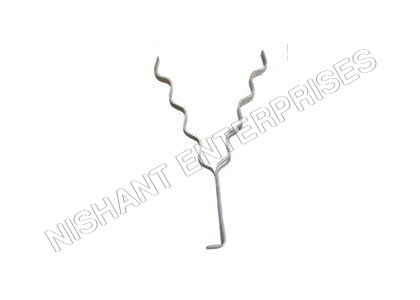

Industrial refractory anchor

Price 400 INR/ Kilograms

Industrial refractory anchor Specification

- Finishing

- Smooth Finish

- Weight

- Variable as per size and shape

- Capacity

- High temperature resistance up to 1600C

- Surface Treatment

- Electropolished / Galvanized / Passivated

- Material

- Stainless Steel / Mild Steel

- Type

- V Shape, Y Shape, U Shape, Zig Zag, or Custom

- Length

- 50 mm to 300 mm (customizable)

- Diameter

- 3 mm to 16 mm

- Product Type

- Industrial refractory anchor

- Surface

- Polished or Plain

- Grade

- SS 304, SS 310, SS 316, MS

Industrial refractory anchor Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 100 Kilograms Per Day

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- in carton boxes and wooden boxes.

- Main Domestic Market

- All India

About Industrial refractory anchor

We feel proud to introduce ourselves as the leading manufacturer, exporter and supplier of Industrial Refractory Anchor. This anchor is widely demanded in the market owing to its easy installation, compact design, ability to withstand adverse conditions and enhanced durability. To manufacture this Industrial Refractory Anchor, we use high grade raw materials keeping in mind the set industry norms. Our team of quality controllers tests each anchor on various parameters before dispatching to the clients.

Exceptional Corrosion and Heat Resistance

Designed for longevity, our refractory anchors boast superior corrosion resistance and maintain integrity even at temperatures reaching 1600C. Their durability ensures reliable performance in harsh environments such as furnaces, kilns, and reactors, reducing downtime and maintenance costs.

Versatile Customization to Meet Every Need

Clients can choose from a variety of shapes (V, Y, U, Zig Zag, or custom), grades (SS 304, SS 310, SS 316, or MS), and finishes (polished, plain, electropolished, galvanized, passivated) to suit specific applications. Sizes and weights can also be tailored for optimal component fit and performance.

Easy Installation and High Strength

Our refractory anchors offer flexible installation through both welding and mechanical fixing, ensuring a strong, secure attachment to refractory linings. With tensile strength exceeding 500 MPa, these anchors support heavy loads and withstand thermal cycling without compromising safety.

FAQs of Industrial refractory anchor:

Q: How are industrial refractory anchors installed in high-temperature environments?

A: Industrial refractory anchors can be installed using either welding or mechanical fixing methods, depending on project requirements and site conditions. Both techniques ensure secure anchoring of refractory linings to substrates, offering durability and safety in extreme environments.Q: What materials and grades are available for refractory anchors?

A: We manufacture refractory anchors using stainless steel grades such as SS 304, SS 310, SS 316, and mild steel. This range allows clients to select the ideal combination of corrosion resistance, temperature tolerance, and mechanical strength for their specific industry needs.Q: When should customized refractory anchors be considered?

A: Customized refractory anchors are ideal when specific shapes, sizes, grades, or finishes are required to meet unique application challenges, such as space constraints, particular load requirements, or specialized operating environments found in steel, cement, petrochemical, or power plants.Q: Where are these refractory anchors commonly used?

A: Our refractory anchors are widely used in steel mills, cement plants, petrochemical facilities, and power plants wherever high-temperature processes demand stable, long-lasting refractory linings secured by reliable anchoring systems.Q: What is the typical process for manufacturing these anchors?

A: Manufacturing involves selecting appropriate raw material, precision forming the anchors into V, Y, U, Zig Zag, or custom shapes, and applying finishing treatments like polishing, electropolishing, galvanizing, or passivation, all while ensuring smooth surfaces and adherence to specified dimensions.Q: How do corrosion resistance and tensile strength benefit refractory anchor applications?

A: High corrosion resistance guarantees durability against chemical attacks, while tensile strength exceeding 500 MPa ensures the anchors withstand mechanical stresses and thermal cycling, maintaining refractory lining stability and prolonging equipment life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Anchor Products Category

SS Refractory Anchors

Price 400 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : SS Refractory Anchors

Material : Other, Stainless Steel (SS)

Finishing : Other, Polished

Weight : Varies as per size and type

Y Shape Refractory Anchors

Price 400 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Product Type : Y Shape Refractory Anchors

Material : Other, Stainless Steel, Mild Steel, Nickel Alloy, Inconel, Hastelloy, Monel

Finishing : Other, Bright, Smooth

Weight : As per dimension and material selection

Furnace Anchor

Price 400 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Product Type : Furnace Anchor

Material : Other, Stainless Steel

Finishing : Other, Bright / Smooth finish

Weight : As per specification

Industrial Refractory Anchor

Price 400 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Product Type : Industrial Refractory Anchor

Material : Other, Stainless Steel / Mild Steel

Finishing : Other, Smooth

Weight : 0.025 kg (approx.)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS