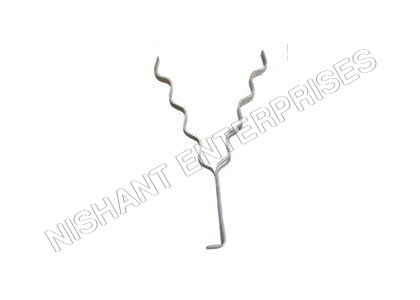

SS Refractory Anchors

Price 400 INR/ Piece

SS Refractory Anchors Specification

- Capacity

- Heavy Duty

- Surface Treatment

- Pickled, Passivated

- Weight

- Varies as per size and type

- Finishing

- Polished

- Material

- Stainless Steel (SS)

- Type

- Length

- 50 mm to 300 mm or as per requirement

- Product Type

- SS Refractory Anchors

- Diameter

- 3 mm to 12 mm

- Surface

- Smooth

- Grade

- SS 304, SS 310, SS 316, SS 321 and other grades

SS Refractory Anchors Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 2 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- in carton boxes and wooden boxes.

- Main Domestic Market

- All India

About SS Refractory Anchors

Leveraging on our vast industry experience, we have emerged as the noteworthy manufacturer, exporter and supplier of SS Refractory Anchors. These anchors are manufactured in conformity with international standards using high grade stainless steel and cutting edge technology. This range of SS Refractory Anchors is known for optimum performance, longer service, compact design, corrosion resistance and easy installation. Clients can avail these anchors in different specifications that can be further customized as per the precise needs of the clients.

Exceptional Heat and Corrosion Resistance

Engineered from high-grade stainless steels, SS Refractory Anchors ensure durability even in extreme heat conditions. Their corrosion-resistant qualities maintain structural integrity in harsh industrial environments, making them ideal for long-lasting performance in furnaces, kilns, and reactors.

Versatile Shapes and Tailored Solutions

With an assortment of shapes like V, Y, Zig Zag, Crook, and C, these anchors cater to diverse installation requirements. Custom designs and specificationsincluding lengths from 50 mm to 300 mm and diameters from 3 mm to 12 mmoffer adaptable solutions tailored to specific projects and industries.

FAQs of SS Refractory Anchors:

Q: How are SS Refractory Anchors typically installed in refractory linings?

A: SS Refractory Anchors can be installed using either welding or mechanical fixing methods, depending on the application and design requirements. The choice of installation method ensures optimal support and stability for refractory linings in high-temperature settings.Q: What are the benefits of using stainless steel refractory anchors over other materials?

A: Stainless steel refractory anchors provide excellent resistance to both corrosion and high temperaturesup to 1600C, depending on the selected grade. This extends the lifespan and reliability of refractory linings, particularly in aggressive industrial environments.Q: When should specific grades such as SS 310 or SS 321 be chosen for refractory anchors?

A: Grades like SS 310 or SS 321 are recommended when operating in environments that demand higher temperature resistance or enhanced oxidation resistance. Selection depends on the thermal and chemical exposure expected during service.Q: Where are SS Refractory Anchors commonly used?

A: These anchors are widely used in industries with extreme heat processes, such as steel plants, cement kilns, power generation boilers, petrochemical furnaces, and other sectors where refractory lining integrity is critical.Q: What shapes and sizes are available for SS Refractory Anchors?

A: The anchors are available in various shapes, including V, Y, U, Zig Zag, Crook, and C, as well as custom configurations. Lengths range from 50 mm to 300 mm, and diameters vary from 3 mm to 12 mm, with flexibility for custom sizing based on project requirements.Q: How does proper packaging contribute to the quality of SS Refractory Anchors during transport and storage?

A: SS Refractory Anchors are packed in gunny bags, carton boxes, or as per customer specification to ensure they remain protected from mechanical damage and contamination during handling, transit, and storage, thereby preserving quality until installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Anchor Products Category

Stainless Steel Refractory Anchors

Price 400 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Material : Other, Stainless Steel

Product Type : Stainless Steel Refractory Anchors

Grade : SS304, SS316, SS310, Inconel, and other alloys

Surface : Smooth, Polished, or Pickled

Y Shape Refractory Anchors

Price 400 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Material : Other, Stainless Steel, Mild Steel, Nickel Alloy, Inconel, Hastelloy, Monel

Product Type : Y Shape Refractory Anchors

Grade : SS 304, SS 310, SS 316, MS, etc.

Surface : Plain, Corrugated, Ribbed

Industrial refractory anchor

Price 400 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Material : Other, Stainless Steel / Mild Steel

Product Type : Industrial refractory anchor

Grade : SS 304, SS 310, SS 316, MS

Surface : Polished or Plain

Furnace Anchor

Price 400 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Material : Other, Stainless Steel

Product Type : Furnace Anchor

Grade : 304 / 316 / 310

Surface : Smooth / Polished

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS