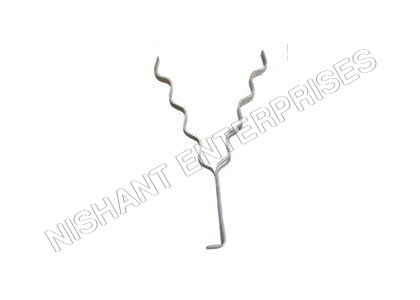

Stainless Steel Refractory Anchors

Price 400 INR/ Kilograms

Stainless Steel Refractory Anchors Specification

- Weight

- Depends on design and size (typically ranges from 10 to 150 grams per anchor)

- Surface Treatment

- Passivated or Pickled, as per specifications

- Capacity

- Designed as per client specification or refractory lining support requirements

- Finishing

- Brushed, Polished, or Custom

- Material

- Stainless Steel

- Type

- V, Y, U, Corrugated, Crook, Zig Zag, or Custom

- Length

- 75 mm to 300 mm (customized as required)

- Diameter

- 3 mm to 12 mm

- Product Type

- Stainless Steel Refractory Anchors

- Surface

- Smooth, Polished, or Pickled

- Grade

- SS304, SS316, SS310, Inconel, and other alloys

- Shape Availability

- V, Y, U, Crook, Double Crook, Zig Zag, Corrugated, Custom shapes

- Packaging

- Cardboard boxes or as per customer requirement

- Temperature Resistance

- Up to 1500°C (Depending on selected grade)

- Installation

- Welded or tied positioning

- Corrosion Resistance

- Excellent, dependent on the alloy used

Stainless Steel Refractory Anchors Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 500 Kilograms Per Day

- Delivery Time

- 2 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- in carton boxes and wooden boxes,

- Main Domestic Market

- All India

About Stainless Steel Refractory Anchors

With rich industry experience, we are able to manufacture, export and supply a wide range of Stainless Steel Refractory Anchors that is suitable for single and dual layer lining, bricks, & ceramics anchors and is used for excellent welding purposes. These anchors are fabricated using quality grade raw materials and advanced technology under the supervision of highly skilled professionals. It is reckoned for corrosion resistance, perfect finish, rugged construction, precise dimensions and durability. We offer this range of Stainless Steel Refractory Anchors in different specifications to meet the varied needs of clients. To ensure their premium quality, these anchors are stringently monitored on various quality parameters.

Versatile Shape and Customization Options

Our stainless steel refractory anchors are available in multiple shapes such as V, Y, U, Crook, Double Crook, Zig Zag, Corrugated, and can be tailored to custom designs. This extensive variety ensures compatibility with diverse refractory lining configurations and meets unique project requirements.

Exceptional Thermal and Corrosion Resistance

Engineered for durability, these anchors can withstand elevated temperatures up to 1500C, depending on the selected alloy. The choice of stainless steel material provides excellent resistance to oxidation and corrosion, making them suitable for harsh industrial environments.

Flexible Packaging and Superior Finish

Each order is packed meticulously in cardboard boxes or as specified by the customer, ensuring secure delivery. With finishing options like brushed, polished, or customized treatments, and surface treatments such as passivation or pickling, the anchors fulfill both performance and aesthetic requirements.

FAQs of Stainless Steel Refractory Anchors:

Q: How are stainless steel refractory anchors installed?

A: Stainless steel refractory anchors can be installed either by welding directly onto the underlying structure or by positioning them with ties, depending on the application and design requirements.Q: What temperature resistance do these anchors provide?

A: Depending on the grade chosen, these anchors can withstand temperatures up to 1500C, making them ideal for high-heat industrial settings such as furnaces and kilns.Q: When should I use custom-shaped anchors?

A: Custom-shaped anchors are recommended when standard V, Y, U, or other common shapes do not meet specific lining configurations, or where unique support is required due to the geometry or stresses in your refractory application.Q: Where is it best to use stainless steel refractory anchors?

A: These anchors are commonly used in the construction and maintenance of refractory linings within industrial furnaces, kilns, cyclones, reactors, and incinerators, especially where high temperature and corrosion resistance are vital.Q: What is the process for selecting the suitable alloy and finish?

A: The appropriate alloy (SS304, SS316, SS310, Inconel, etc.) and finishing (brushed, polished, pickled, etc.) should be chosen based on the operating environment, chemical exposure, and required temperature resistance. Manufacturers typically provide guidance after assessing application requirements.Q: What are the main benefits of using stainless steel refractory anchors from your range?

A: The main benefits include resilience at extreme temperatures, excellent corrosion resistance, adaptability to custom sizes and shapes, and reliable performance that ensures a long service life of refractory linings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Anchor Products Category

SS Refractory Anchors

Price 400 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : SS Refractory Anchors

Material : Other, Stainless Steel (SS)

Surface Treatment : Other , Pickled, Passivated

Grade : SS 304, SS 310, SS 316, SS 321 and other grades

Y Shape Refractory Anchors

Price 400 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Product Type : Y Shape Refractory Anchors

Material : Other, Stainless Steel, Mild Steel, Nickel Alloy, Inconel, Hastelloy, Monel

Surface Treatment : Other , Pickled, Polished, Zinc Plated, Sand Blasted

Grade : SS 304, SS 310, SS 316, MS, etc.

Furnace Anchor

Price 400 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Product Type : Furnace Anchor

Material : Other, Stainless Steel

Surface Treatment : Other , Polished / Passivated

Grade : 304 / 316 / 310

Refractory Casting Y Anchors

Price 400 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Product Type : Refractory Casting Y Anchors

Material : Metal

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS