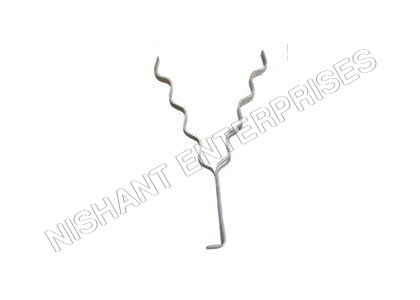

High Temp Refractory Anchor

Price 400 INR/ Kilograms

High Temp Refractory Anchor Specification

- Finishing

- Smooth Finish

- Material

- Stainless Steel (SS304/SS316), Inconel, or Mild Steel

- Length

- 75 mm to 300 mm (customizable)

- Diameter

- 3 mm to 10 mm

- Product Type

- High Temp Refractory Anchor

- Surface

- Polished / Unpolished

- Grade

- SS 304, SS 316, Inconel 601, 330

High Temp Refractory Anchor Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 500 Kilograms Per Day

- Delivery Time

- 2 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- in wooden boxes and carton boxes.

- Main Domestic Market

- All India

About High Temp Refractory Anchor

We are offering High Temp Refractory Anchor, which is manufactured using supreme grade stainless steel and alloy as per the set industry norms. The offered High Temp Refractory Anchor is highly appreciated for light weight, rigid construction, corrosion resistance, compact design and durability, and is thereby, widely demanded in the global market. It is available in different specifications and can be customized as per the requirements of clients. This product is monitored by our team of quality controllers on various predefined parameters.

Versatile Material Choices

Select from stainless steel (SS304, SS316), Inconel 601, 330, or mild steel, depending on your applications requirements. Each material provides unique benefits in thermal stability and corrosion resistance, ensuring reliable performance in harsh industrial settings.

Customizable Dimensions

We offer length options from 75 mm to 300 mm and diameters between 3 mm and 10 mm. Our manufacturing process allows for customization according to client-supplied drawings or specifications, meeting the exact demands of diverse refractory lining techniques.

Reliable Performance and Finish

Designed with a smooth, polished or unpolished surface and excellent finishing, these anchors deliver both durability and enhanced fit for refractory lining. Their silver/metallic color contributes to a professional and clean installation appearance.

FAQs of High Temp Refractory Anchor:

Q: How are high temp refractory anchors installed in refractory linings?

A: These anchors can be fitted either by welding directly into the structure or through mechanical fixing methods, depending on project requirements and anchor material. Both processes securely hold refractory linings in place under extreme temperatures.Q: What benefits do high temperature refractory anchors provide in industrial applications?

A: They ensure structural stability and insulation integrity within kilns, furnaces, and reactors by keeping refractory layers firmly in position, ultimately enhancing operational safety and efficiency.Q: When should I choose a specific material grade for refractory anchors?

A: Selection depends on your applications temperature range and exposure to corrosive environments. Stainless steel (SS304/316) is ideal for moderate to high temperatures, while Inconel alloys offer superior resistance for more aggressive conditions and higher thermal stress.Q: Where are these refractory anchors commonly used?

A: These anchors are extensively utilized in cement plants, petrochemical facilities, power stations, and other industries where reliable refractory attachment is critical for high-temperature process equipment.Q: What is the customization process for refractory anchors?

A: Customization starts with reviewing client-supplied drawings or technical specifications. Our manufacturing team then produces anchors tailored to required dimensions, grades, and finishes, ensuring they meet your projects precise needs.Q: How are these anchors packaged for export and safe delivery?

A: We use sturdy carton boxes or wooden crates to protect the anchors during transportation, ensuring they remain undamaged and ready for immediate installation upon arrival.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Anchor Products Category

SS Refractory Anchors

Price 400 INR / Piece

Minimum Order Quantity : 50 Pieces

Product Type : SS Refractory Anchors

Material : Other, Stainless Steel (SS)

Diameter : 3 mm to 12 mm

Type : Other, V Shape, Y Shape, U Shape, Zig Zag and other custom shapes

Y Shape Refractory Anchors

Price 400 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Product Type : Y Shape Refractory Anchors

Material : Other, Stainless Steel, Mild Steel, Nickel Alloy, Inconel, Hastelloy, Monel

Diameter : 3 mm to 16 mm

Type : Other, Y Shape

Industrial refractory anchor

Price 400 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Product Type : Industrial refractory anchor

Material : Other, Stainless Steel / Mild Steel

Diameter : 3 mm to 16 mm

Type : Other, V Shape, Y Shape, U Shape, Zig Zag, or Custom

Stainless Steel Refractory Anchors

Price 400 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Product Type : Stainless Steel Refractory Anchors

Material : Other, Stainless Steel

Diameter : 3 mm to 12 mm

Type : Other, V, Y, U, Corrugated, Crook, Zig Zag, or Custom

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS